PTC Product Manufacturing Solutions for Different Industries

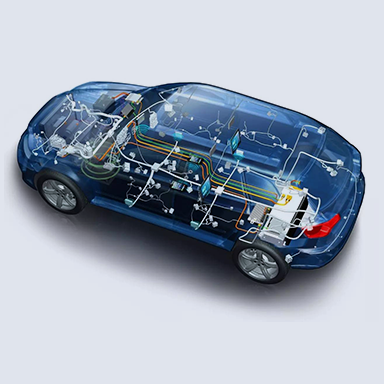

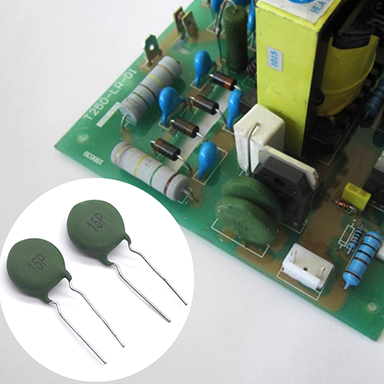

Improve your product performance and quality! We offer a wide range of PTC product solutions, covering PTC thermistors, PTC heating elements, PTC heaters processes, ensuring excellent durability and precision manufacturing. From electronics and electrical to smart home and consumer electronics industry products, our expertise brings unlimited possibilities. Experience our high-performance PTC product applications now!

PTC Product Manufacturing Solution

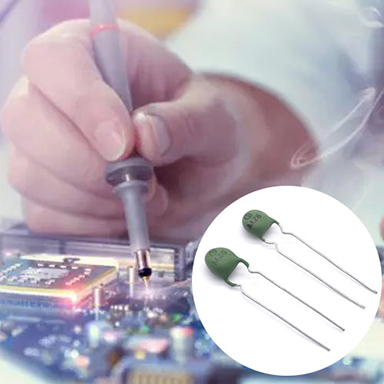

Turn your product vision into reality! We provide end-to-end solutions from design to mold manufacturing and production based on your unique needs. Our PTC thermistor manufacturing technology covers processes such as material preparation, molding, sintering, electrode preparation, performance testing, etc. to ensure excellent durability and precision. Experience our excellent seamless manufacturing services now!

PTC Thermistor Manufacturing Process

The manufacture of PTC thermistors begins with a mixture of barium carbonate, titanium oxide and other materials that produce the desired electrical and thermal characteristics, which are ground, mixed and compressed into discs or rectangles and then sintered, preferably at a temperature below 1400°C. Afterwards, they are carefully joined together, equipped with connecting elements depending on the model and finally coated or encapsulated.

The manufacturing of PTC thermistors begins with powder making

The raw materials such as barium carbonate and titanium oxide are accurately weighed and proportioned, mixed with deionized water, and ball milled. The materials are mixed evenly through ball milling. Then the powder is dried and spray granulated. Before going to the next step, the appearance, water content, fluidity, density and electrical properties of the PTC thermistor powder should be carefully checked.

PTC Pressing

Put the powder into the tablet press and press it into pills, tablets, sticks, tablets, etc. according to the requirements. And carefully check the appearance, size and weight of the pills.

Sintering workshop

The disc is placed in a crucible and sent to a sintering kiln for firing. After high-temperature sintering, it becomes a semiconductor and forms a resistance value. After sintering, appearance, resistance, and withstand voltage tests are required.

PTC electrode saturation

The bottom ohmic electrode and the surface electrode need to be made through processes such as silver printing, silver baking, and electrode saturation. After the electrode process is completed, the appearance, ohmic contact, solderability, adhesion, etc. need to be inspected.

About Us

Quality and Health, Enjoy Life

Dongguan Tianrui Electronics Co., Ltd. was founded in 2010. It is a high-tech enterprise specializing in the research, development, production and sales of positive temperature coefficient (PTC) thermistor components. Our company covers an area of 5,000 square meters and has a full set of automated production equipment, complete special testing instruments and testing methods. The annual production volume is nearly 100 million. The series of PTC components produced by our company strictly implement relevant international standards, national standards and industry standards.

Provide high quality products and services

Quality as one, service forever

Customer Cases

PTC thermistor: a revolutionary breakthrough in overcurrent protection for electric welders

The application of thermistors in the field of electric welders marks a major leap forward in electric welders' major loop protection...

Innovative application of PTC heating sheet in electric mosquito liquid heater

In the upgraded research and development of electric mosquito liquid heater, we use high-precision PTC heating sheet as the...

Innovative application of customized PTC heaters in the beauty and hairdressing industry

With the improvement of equipment safety and performance requirements in the beauty and hairdressing industry, traditional...

Innovative application cases of customized PTC heaters in high-end heaters

As consumers' requirements for comfort and safety of home heating equipment continue to increase, customers face a key...

Our Partners

We serve customers across five continents, working together and growing together.