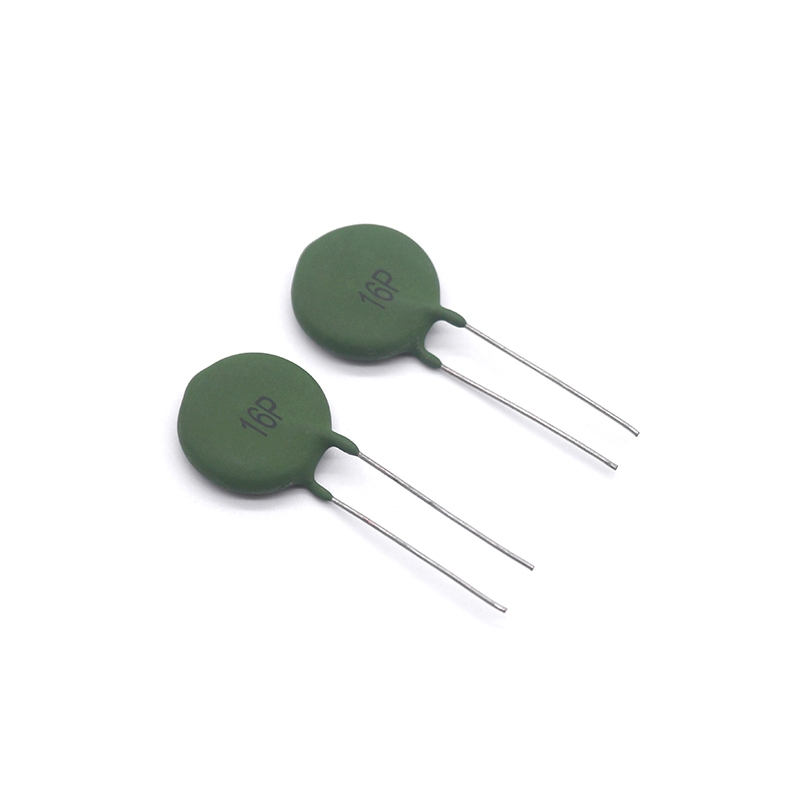

Product Description

15P, 16P, and 19P welding machine PTC thermistors are designed specifically for use in corresponding inverter welding machines as inrush current suppressors. Their core function is to effectively suppress the massive surge current (inrush current) generated when AC power flows through the rectifier bridge and charges the large-capacity filter capacitors at the moment the welding machine is turned on. This protects the rectifier bridge, electrolytic capacitors, and critical IGBT/MOSFET switching transistors from damage. These PTC thermistors are crucial for ensuring reliable welding machine startup and long-term stable operation.

Specification

Product Name: 15P Welding Machine PTC Thermistor

R25 : 100Ω±25%

Diameter : 15mm

Thickness: 7mm

Lead Spacing: 5mm

Switching Temperature : 120℃

Breaking Down Voltage : 600V

Non-operating Rated Current: 100mA

Typical Trip Current: 200mA

Application : Welding Machines

Color : Green

Features

Smart resistor features: They exhibit a unique positive temperature coefficient effect. At room temperature, they exhibit low resistance (e.g., 5Ω, 8Ω, 10Ω), effectively limiting current. Upon application of power, they rapidly transition to a high resistance state, minimizing power consumption and minimizing impact on the welder's normal operation.

High reliability and self-healing: As a solid-state component, they lack mechanical contacts, resulting in a long lifespan and strong shock resistance. After a single start-up, they automatically cool down and reset, preparing for the next start-up.

Model compatibility: For different power welders, such as 15P, 16P, and 19P, the PTC's zero-power resistance, maximum steady-state current, withstand energy (I²t), and volume are precisely designed and matched to ensure optimal current limiting performance in their respective systems. They are not interchangeable.

High safety: In the event of a serious fault such as a short circuit in the subsequent circuit, the PTC will continue to heat up due to the excessive current and remain in a high-resistance state, providing a certain degree of current limiting protection. They often work in conjunction with a fuse to form a dual protection circuit.

Application

This series of PTC thermistors is primarily used in the power input circuit of inverter DC welding machines. A typical application circuit connects them in series between the AC input line and the rectifier bridge. At power-on, they function as a current-limiting resistor. Subsequently, the welding machine's mainboard controls a parallel relay or thyristor to energize, shorting the high-resistance PTC, allowing the main current to flow through the relay contacts and ensuring full welder power output. Consequently, they are widely used in the power modules of 15P, 16P, and 19P inverter welding and cutting machines, as well as various other MOSFET/IGBT inverters. They are essential protection components in modern welding machine designs.